| << back to overview |

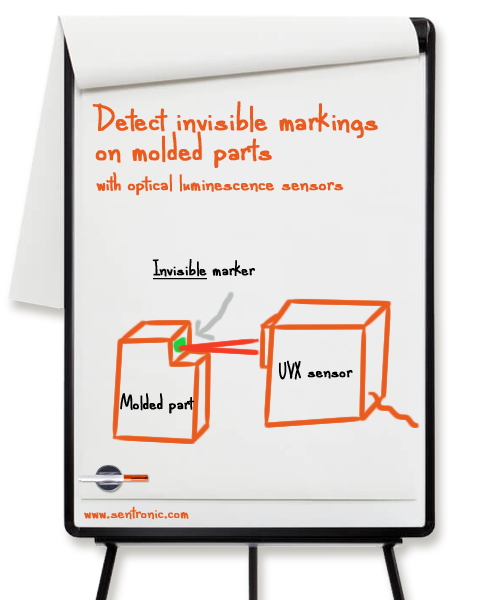

| Solution for the detection of invisible markers |

| Using luminescence sensors to advantage Fixed points or markings are essential for machines to detect position, location and presence. However, it is of course not possible to draw a dot or cross on every workpiece, as these markings are disturbing after machining. This is where invisible, ultraviolet markings come into play, which are only detected by the UV sensor, but not by the human eye. There are also washable UV inks that disappear completely after cleaning the workpiece. In the wood industry, visible UV markers such as crayon are often used to show the machine where the areas to be repaired are. Or for quality control, as overflowing glue and fungicides can be detected with the UV sensors. |

|

|

|

|

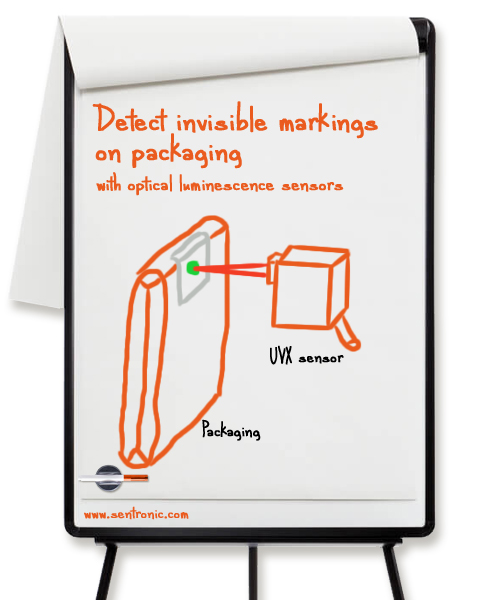

| Using the invisible as an advantage Packaging should be beautiful, there is no place for markings. But the packaging machine needs them to work. When is folded, cut or glued, all information that the machines need for fast and reliable packaging. Invisible markings can be used to remedy this situation. These are not visible to the human eye, but are visible to the luminescence sensor on the machine. This means that visually appealing packaging can be realized without any visible markings at all. Ultraviolet markings that are invisible to humans are used for product protection. In this way, originals can be distinguished from counterfeits. |

|

|

|

|

| Simple solutions are often the best solutions. This is about food for thought, ideas and possibilities. Our technicians are happy to discuss your concerns via LiveCall, chat, email or telephone. The basic ideas shown here can be rebuilt or extended according to your needs! |

|

| Content: #detect markers #detect luminors #detect brighteners #detect UV labels #detect optical brighteners #detect invisible brighteners #detect invisible luminors #detect invisible markers #detect labels #detect luminescence #detect phosphorescence #detect fluorescence #luminescence sensors #luminescence sensors #UV sensors #detecting markers #detecting luminors #detecting brighteners #detecting optical brighteners #detecting invisible brighteners #detecting invisible luminors #detecting invisible markers #detecting labels #detecting luminescence #detecting phosphorescence #detecting fluorescence |