| << back to overview | ||||||||||||||||||||||||||

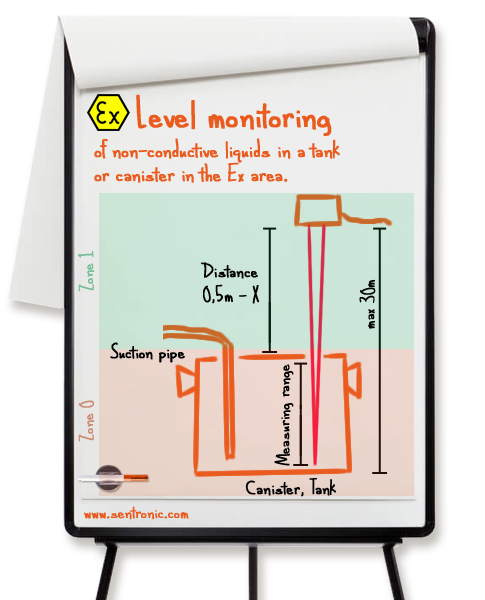

| Solution approaches from the area of level monitoring in Ex area | ||||||||||||||||||||||||||

| Detecting non-conductive liquids in tanks or canisters in hazardous areas For non-conductive liquids such as soap, classic solutions such as capacitive sensors or level relays are not applicable, as these require a certain conductivity. This is where measuring laser sensors come into play. They are able to reliably detect the level in the Ex range through small openings in the tank or canister. With an appropriate laser sensor, this solution also works in a non-hazardous environment. |

||||||||||||||||||||||||||

|

||||||||||||||||||||||||||

| Simple solutions are often the best solutions. This is about food for thought, ideas and possibilities. Our technicians are happy to discuss your concerns via LiveCall, chat, email or telephone. The basic ideas shown here can be rebuilt or extended according to your needs! |

||||||||||||||||||||||||||

|

||||||||||||||||||||||||||

| Content: #Ex Level control #Ex Level measurement #Ex Level display #Ex Level liter #Ex Level percent #Ex Level monitoring #Ex Level control #Ex Level measurement #Ex Level display #Ex Level monitoring #Ex Level control #Ex Level monitoring #Ex Level display #Ex Level control #Ex Level monitoring #Ex Level display #Ex Level monitor #Ex Level monitor #Ex Level measurement |

||||||||||||||||||||||||||