| << back to overview |

| Approaches for solutions with the PEL system (Gauging switches) |

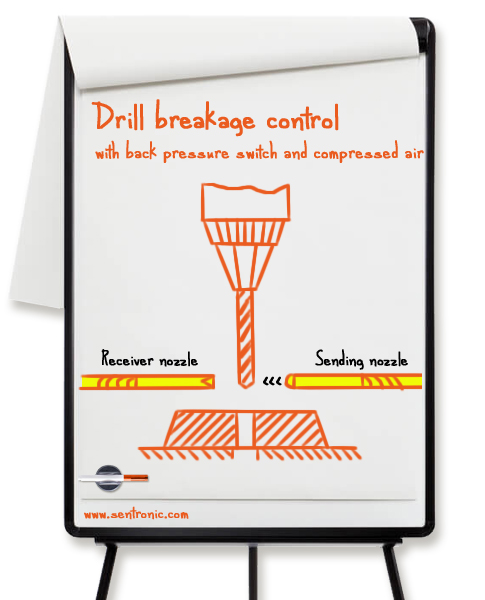

| Reliably detect broken drill bit Detecting a broken drill bit in a rough and dirty environment is very difficult for standard sensor technology. Splashing cooling water and flying chips very often deceive the sensors. The PEL system, which works with compressed air, cannot be fooled. It is therefore self-cleaning and is not affected by the chips. An air barrier is created by means of two nozzles, which is monitored by the dynamic pressure switch. In the event of a drill breakage, a signal is output immediately. This can be purely pneumatic or also digital for a control system, for example. The sensitivity of the system can be set on the pitot switch. |

|

|

|

|

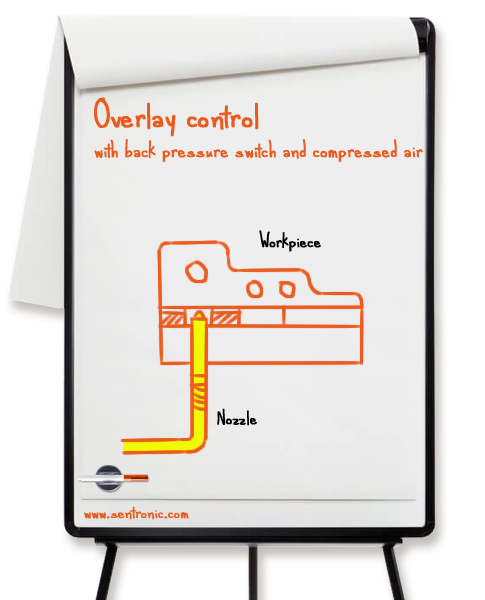

| Checking the support of a workpiece With a lot of dirt and chips in automated, micrometer-precise CNC manufacturing, it is important that workpieces rest straight and true after being turned or positioned by a robot. There must be no chips between the workpiece and the support, as this affects accuracy enormously. With the PEL system, exactly this exact contact is monitored. The smallest gaps are detected by the system and the release for further processing is refused. The use of compressed air makes the system self-cleaning. |

|

|

|

|

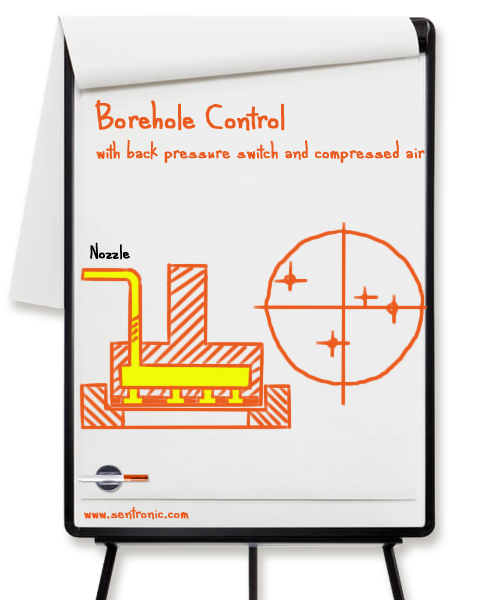

| Checking boreholes by means of back pressure switch Using compressed air and the PEL system, drill holes can be conveniently checked. The rough and dirty environment of CNC machines cannot harm the system. Due to the compressed air it is self-cleaning and is not affected by cooling water or chips. The sensitivity of the system can be adjusted at the back pressure switch. |

|

|

|

|

| Simple solutions are often the best solutions. This is about food for thought, ideas and possibilities. Our technicians are happy to discuss your concerns via LiveCall, chat, email or telephone. The basic ideas shown here can be rebuilt or extended according to your needs! |

|

| Content: #Drill Breakage Control #Drill Breakage Control #detect broken drill #detect broken drill #detect broken drill #detect broken drill #Drill Breakage Sensor #Back Pressure Switch #PEL Switch #PEL System #APA1 #Position Control #Position Detection #Position Detection #Position Control Sensor #Position Control Sensor #Presence Control #Presence Control Sensor #Drill Control #Punch Control #Punch Control Sensor #Punch Control Sensor #Punch Control Automatic |