| << back to overview | ||||||||||||||||||||||||||||

| Solution approaches from the area of Filter monitoring | ||||||||||||||||||||||||||||

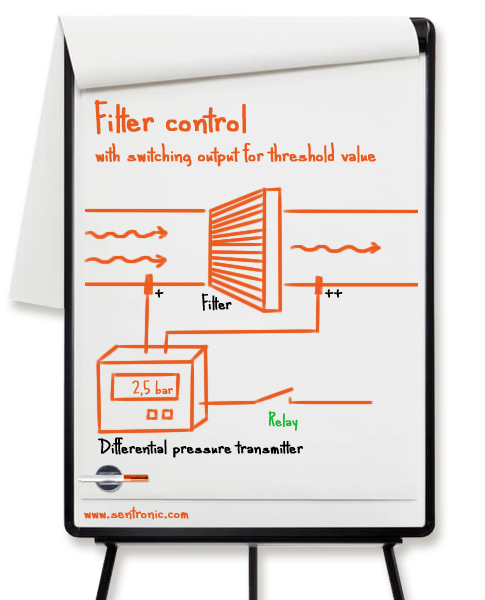

| Protect filters from clogging Clogged filters greatly affect a process. However, monitoring the filters is not easy. The environment is usually dusty and unsolvable for standard sensor technology. By means of a small trick, however, monitoring works reliably. One measures the pressure before the filter and after the filter with a differential pressure transmitter. If the difference exceeds the set value, the filter is clogged and must be changed. This is signaled with a switching output in this solution. The signal can be transmitted to a lamp or to a controller. |

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

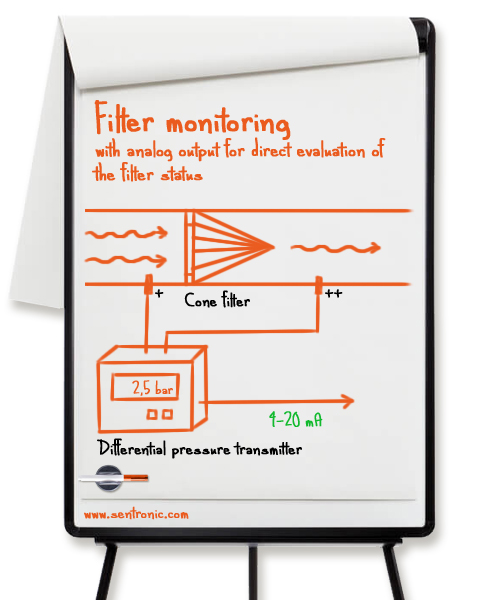

| Detect the condition of the filter Clogged filters greatly affect a process. However, monitoring the filters is not easy. The environment is usually dusty and unsolvable for standard sensor technology. By means of a little trick, however, monitoring works reliably. One measures the pressure before the filter and after the filter with a differential pressure transmitter. With this solution, the transmitter transmits the differential pressure as a process signal (e.g. 4-20mA) to a controller. This means that the condition of the filter is known at all times, and filter changes can be scheduled at reasonable machine downtimes. |

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Simple solutions are often the best solutions. This is about food for thought, ideas and possibilities. Our technicians are happy to discuss your concerns via LiveCall, chat, email or telephone. The basic ideas shown here can be rebuilt or extended according to your needs! |

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

| Content: #Filter control #Filter monitoring #Monitoring filter #Control filter #Differential pressure display #Differential pressure switch #Differential pressure measurement #Differential pressure measurement #Gauge filter #Air volume #Air flow meter |

||||||||||||||||||||||||||||